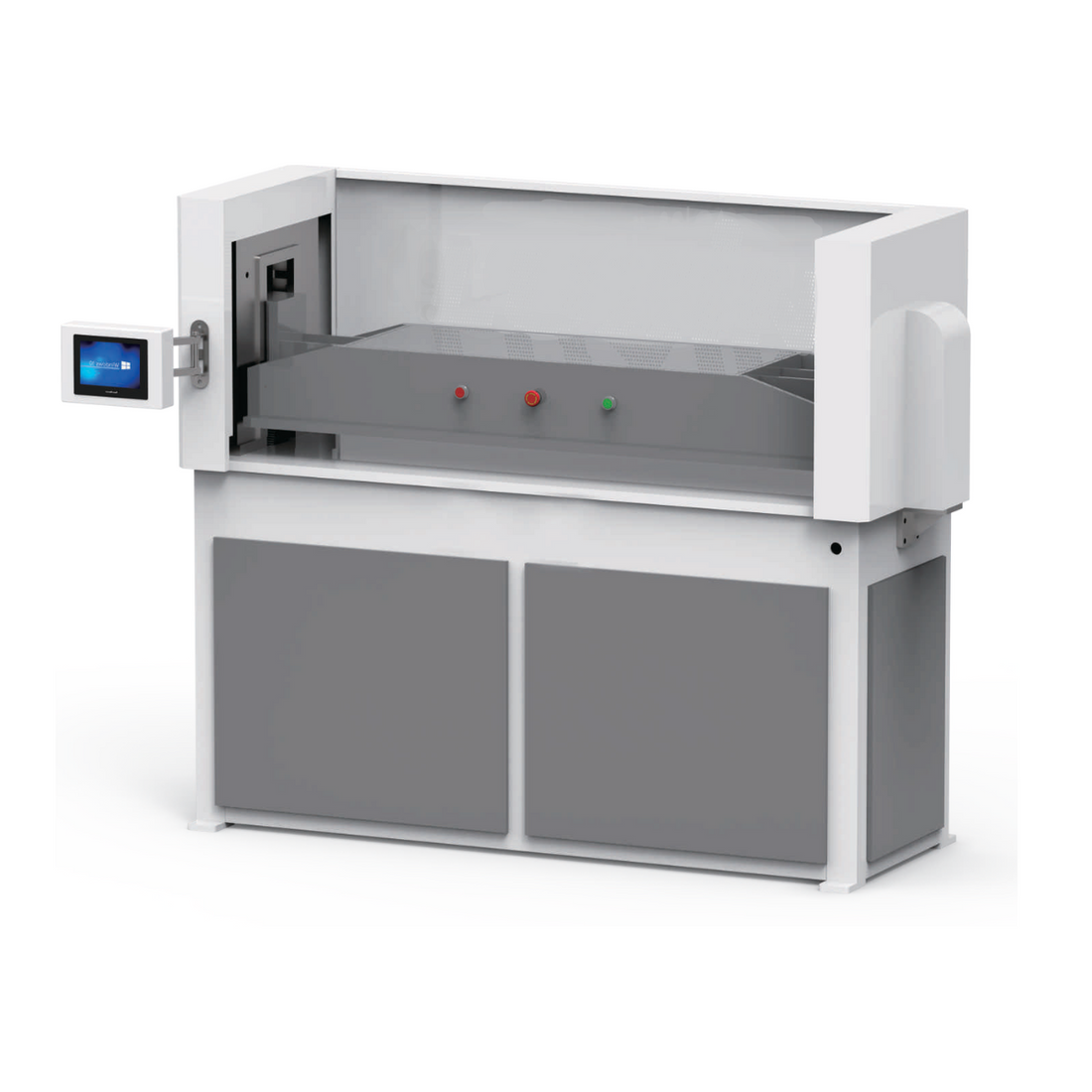

Hammerhead Servo-Electric Full Beam Press

SERVOBEAM SERIES

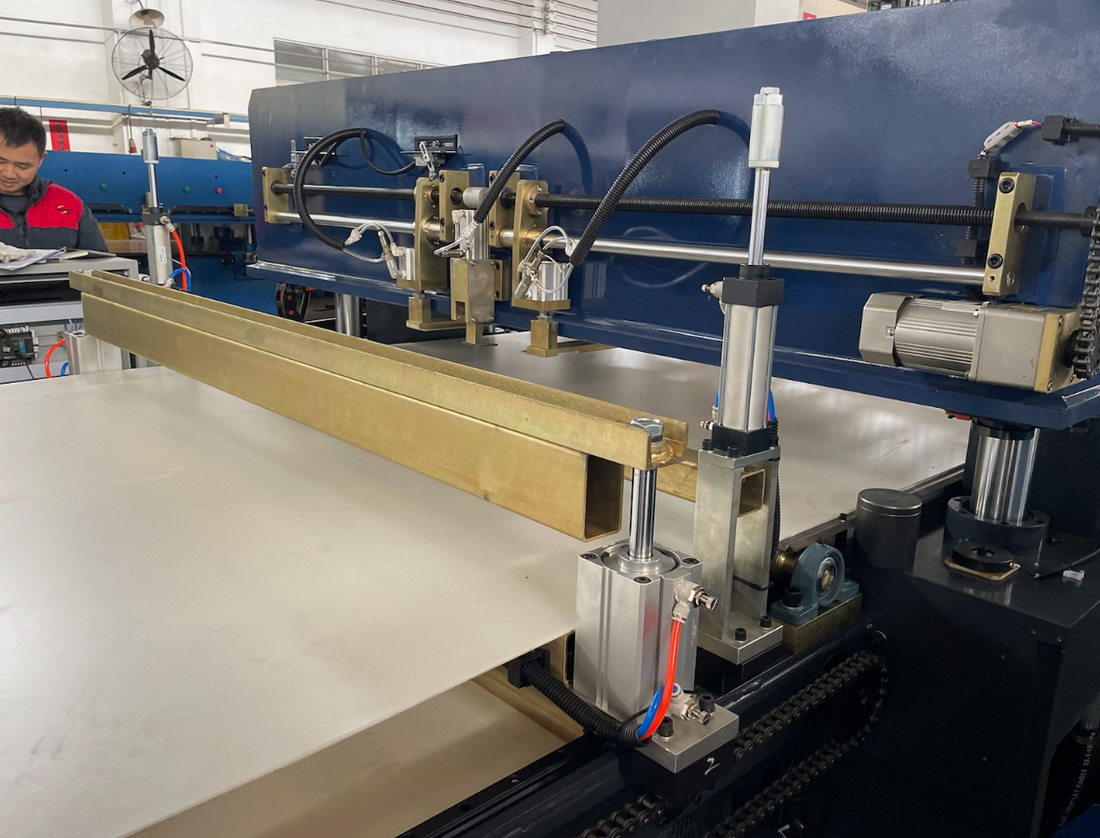

The ServoBeam Servo-Electric Full Beam Press is our largest-format die cutting solution for sensitive environments and cleanrooms. This system uses two set of gears with guideposts, connected to a servo by chains, to create cuts with phenomenal accuracy up to ±0.003". This system boasts up to a 65% increase in energy-efficiency and up to 70% noise-reduction compared to hydraulic models.

Features

Base Features:

• Intuitive software & touchscreen controls

• Encoder-based cutting-depth setting

• Compression counter & hour counter

• Safety light curtains & caging

Safety Features:

• Recipe-saving technology

• Two handle/button operation with anti-tiedown and anti-double-click functionality

• Thermal overload protection

• Phase monitoring & over-voltage protection

Benefits

• The servo-driven functions of this press make it completely non-hydraulic, the friendliest type of machine for cleanroom manufacturing conditions.

• This machine is virtually silent when the machine is sitting idle and makes very minimal noise during compressions.

• With a fully enclosed cutting area, safety light curtains, and fully covered pinch-point areas, this machine is among the safest machines of its type on the market.

drawbacks

• This servo-powered system doesn’t carry any significant speed benefits over standard hydraulic machines.

• This machine has a very limited tonnage range compared to hydraulic beam presses.

• The software and some machine features may be moderately complex for some machine operators.

Products from this series

Get a Quote

We offer free, no-pressure consultations and we typically respond within 24 hours.